Understanding Dimensional Weight in LTL Freight

In the world of Less Than Truckload (LTL) shipping, cost and efficiency hinge on how much space cargo occupies—sometimes more than its actual weight. Dimensional weight (often called DIM weight) is the metric carriers use to account for packages that are lightweight but consume significant trailer space. For shippers unaware of how dimensional weight factors into quotes, the result can be unexpected reweigh fees and inflated invoices.

This article reveals why dimensional weight matters, how to calculate it, and strategies to keep your shipping costs in check. Whether you’re sending smaller e-commerce parcels or sizeable but low-density loads, mastering dimensional weight ensures fair carrier rates and fewer mid-transit surprises.

Introduction

The Rise of Lightweight but Bulky Shipments

E-commerce has popularized products that may not weigh much but occupy lots of space—think foam pillows, clothing in protective boxes, or lightweight promotional displays. Traditional weight-based pricing didn’t reflect the true cost of hauling these bulky but lighter goods. Hence, carriers introduced dimensional (or “cube”) pricing to recoup space-related expenses.

Why Dimensional Weight Matters for Carriers

A trailer can only hold so many cubic feet, no matter how light the cargo is. If large, “airy” shipments fill up the trailer, carriers can’t load heavier freight, losing potential revenue. Dim weight charges ensure that each shipper pays proportionally for the footprint (volume) consumed, balancing out the cost of partial trailer loads.

Defining Dimensional Weight

How Dimensional Weight Differs from Actual Weight

- Actual Weight: The scale reading—simply how many pounds the shipment weighs.

- Dimensional Weight: A formula-based “theoretical” weight tying your cargo’s size to standard densities. Carriers compare whichever metric is greater—the real scale weight or the dim weight—and bill you accordingly.

Key Calculations and Formulas

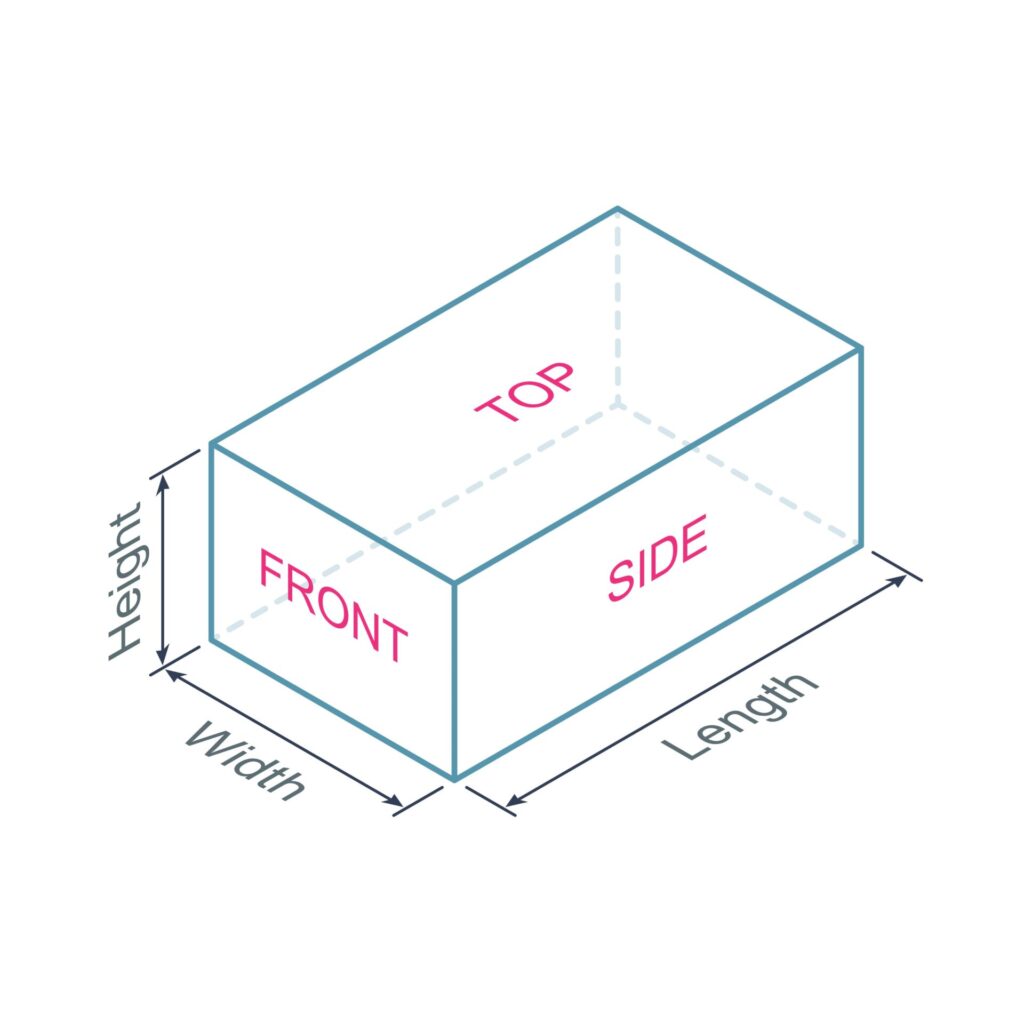

A common formula for dimensional weight (in pounds) is:

Dim Weight (lbs)=Length (in)×Width (in)×Height (in)Dim Factor\text{Dim Weight (lbs)} = \frac{\text{Length (in)} \times \text{Width (in)} \times \text{Height (in)}}{\text{Dim Factor}}Dim Weight (lbs)=Dim FactorLength (in)×Width (in)×Height (in)

Dim factor can vary but might be 166 or 194 for domestic shipments (or 139 for international, etc.). For instance, a large but lightweight box can yield a dim weight exceeding its actual scale weight.

The Impact on LTL Shipping Costs

When Dimensional Weight Exceeds Actual Weight

If a product’s packaging is primarily air—like large protective cushions or foam containers—the shipment’s dim weight can skyrocket above the scale reading. Carriers then bill based on that higher figure, preventing profit loss from half-empty trailer capacity.

Avoiding Reweigh or Reclassification Fees

Declaring the correct dimensions from the start is crucial. Understating a box’s size triggers carrier remeasurement mid-transit, leading to reclassification or surprise surcharges. This scenario is preventable with careful measurement or with dimensioning equipment that automatically calculates the correct dimensional weight.

Accurate Measurement Techniques

Capturing Length, Width, and Height Correctly

Always measure your shipment’s longest points—if a box bulges or has protrusions, include those in the length/width/height. Round each dimension up to the nearest inch. Stacking items on a pallet? Tally the overall dimensions of the entire pallet, not just the product boxes.

Using Scales and Dimensioners

Small shipments might be measured manually, but for higher volumes or large LTL setups, automated dimensioners scan and weigh each load. This precision ensures consistent data, preventing any dispute about misreported package sizes.

Strategies to Minimize Dimensional Weight

Optimizing Packaging and Reducing Air Space

Right-sizing your packaging is the simplest fix. For fragile goods, using dense, protective materials can shrink overall volume if done effectively—like custom foam molds instead of large boxes stuffed with air pillows. Reducing empty space not only curbs freight charges but also lessens packaging waste.

Collaborating with Carriers on Volume Discounts

For recurring shipments or predictable lanes, carriers sometimes accommodate consistent volumes at slightly lower dim weight rates, or they round in your favor if you prove reliable. Volume-based or contract pricing can offset dimensional surcharges, especially if you regularly dispatch loads that teeter near class or weight break thresholds.

Freight Class and Dimensional Weight

NMFC Codes and Density Calculations

In Less Than Truckload (LTL), the National Motor Freight Classification (NMFC) system establishes classes for diverse commodity types. Density is among the biggest factors: items with minimal density but large footprints typically see higher freight classes—and thus higher rates. Aligning accurate dimensions with NMFC codes wards off costly reclassification surprises.

Handling Low-Density, High-Value Goods

High freight class signals more costly shipping. If your products are both bulky and pricey (e.g., specialized medical devices), consider additional coverage or declared value. Carriers expect compensation for using up trailer space, while you must ensure liability coverage matches the shipment’s actual worth.

Technology and Tools for Precise Dimensions

Automated Dimensioning Equipment

State-of-the-art dimensioners use lasers or 3D sensors to measure each shipment. They capture length, width, height, and sometimes weight automatically, storing data for the Bill of Lading and TMS. This eliminates human error—particularly beneficial for shipping frequent, varied-size items.

TMS Integration for Real-Time Quotes

A robust Transportation Management System can connect with dimensioners, pulling accurate dimension data directly into the booking interface. Shippers immediately see if their load triggers a dim weight rate, enabling them to refine packaging or weigh out other shipping methods (like partial truckload) before finalizing.

Negotiating Rates and Managing Costs

Bundling Orders or Using Consolidation

If your cargo is consistently dimension-heavy but light in actual pounds, combining multiple shipments into fewer, bigger loads might yield a more favorable cost ratio. Some 3PLs or brokers also run consolidation programs, merging small loads from various clients into shared LTL shipments, balancing out dimension-heavy freight with heavier goods.

Declared Value vs. Dim Weight Implications

Declaring a higher cargo value to recoup potential damage or loss can also boost your shipping bill if the load is considered dimensionally heavier. Evaluate whether the extra coverage justifies potential higher rates. Often, investing in better packaging or partial truckload could be cheaper overall for frequently shipped bulky cargo.

Best Practices for E-Commerce and Partial Loads

Custom Box Sizes for Reduced Dim Weight

E-commerce retailers shipping large but lightweight items, like bedding or decorative pieces, should explore custom-sized boxes instead of oversize standard boxes. By minimizing empty space, you reduce the dimensional weight rating. Taking time to calibrate box designs to actual product dimensions can pay dividends monthly or annually in decreased shipping costs.

Reevaluating Product Dimensions and Packaging

Continuous iteration is key. If your product lines change or if you receive multiple reclassification warnings from carriers, it’s time to re-check actual item sizes, packaging approach, and possibly transition to collapsible or modular solutions that cut the dimension. This approach likewise improves the unboxing experience, reducing shipping overhead while pleasing customers.

Conclusion

Dimensional weight stands as a pivotal factor in LTL shipping costs, ensuring carriers recoup the true expense of hauling bulky but light freight. For shippers, mastering the nuances of dimensioning, measuring precisely, and optimizing packaging can drastically reduce shipping costs—and surprises—in partial load scenarios. By investing in better technology (like automated dimensioners), forging strong relationships with carriers, and frequently reassessing packaging strategies, businesses can mitigate or dodge excessive dim weight fees.

For those new to LTL or scaling up, the message is clear: incorporate dimensional weight calculations into your standard operating procedures. Doing so yields predictable shipping budgets, fewer reweigh disputes, and a more refined approach to shipping and logistics overall.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.