LTL Freight 101: A Beginner’s Guide

Less Than Truckload (LTL) shipping has become a linchpin for businesses that don’t require the entire capacity of a trailer but still need consistent, reliable freight movement. Although LTL might appear simpler than renting a full truck, it involves its own intricate rules around classification, handling, and pricing. This comprehensive guide offers expanded insights into the essentials of LTL—from weight limits and freight class to packaging and tracking—helping newcomers build a solid foundation for their shipping operations.

By mastering these fundamentals, you’ll learn how to navigate complexities around freight rates, multiple stops, damage risks, and a host of add-on services. Ultimately, whether you’re shipping a couple of pallets monthly or orchestrating a steady flow of partial loads each week, a thorough understanding of LTL shipping empowers you to reduce overhead, improve on-time performance, and keep customers satisfied.

Introduction

The Growing Demand for LTL Shipping

As e-commerce and just-in-time production push companies to ship smaller batches more frequently, LTL has become indispensable. In the past, businesses might wait until they had enough cargo to fill an entire truck; now, speed to market trumps volume consolidation. This shift translates to greater reliance on partial truckloads—a sweet spot LTL perfectly occupies. Yet, frequent partial shipments require meticulous planning around carriers, schedules, and cost structures.

Balancing Flexibility with Complex Handling

Sharing a truck with multiple shippers keeps costs lower but also involves more frequent loading/unloading and cross-docking. Therefore, while LTL offers the boon of flexible shipping for smaller loads, it calls for heightened attention to packaging integrity, labeling accuracy, and the potential for additional services or surcharges. Recognizing these complexities ensures you optimize LTL’s benefits without overshooting your budget or timeline.

Understanding the Fundamentals of LTL Freight

Defining Less Than Truckload

Less Than Truckload shipping splits trailer space among multiple customers shipping partial loads. Each shipper is billed according to the space (or weight) their cargo occupies, along with the general route or lane used. This method is cost-effective if you consistently ship cargo falling within 150–15,000 pounds or requiring only a few pallets at a time.

How LTL Differs from FTL and Parcel

- FTL (Full Truckload): A dedicated trailer for one shipper’s goods, typically used for heavier, time-sensitive, or high-value loads.

- Parcel: Small packages (often under 150 lbs). Shippers opt for FedEx, UPS, DHL, or postal services for single box shipments.

- LTL: The in-between category, perfect for shipments too large for standard parcel carriers but too small to justify a full trailer.

Core Components of LTL Shipping

Weight Thresholds and Freight Class Basics

Although exact definitions vary by carrier, shipments above 150 lbs and below 10,000–15,000 lbs generally qualify for LTL. The National Motor Freight Classification (NMFC) system assigns a freight class (50–500) based on density, stowability, handling, and liability. The higher the class, the higher your rate per hundredweight (cwt).

Multiple Stops and Cross-Docking

An LTL load often passes through multiple terminals for consolidation or transfer, known as cross-docking. This approach helps carriers fill trailers efficiently but can extend transit times and increase the risk of damage if goods aren’t packaged securely.

Advantages of LTL for Modern Businesses

Cost-Efficiency and Frequency

Paying only for occupied space means smaller shipments can move cost-effectively—rather than paying for a half-empty truck. This allows frequent shipments, keeping inventory levels lean and responsive to changing customer demand. For e-commerce sellers, it ensures product availability without the overhead of large, infrequent deliveries.

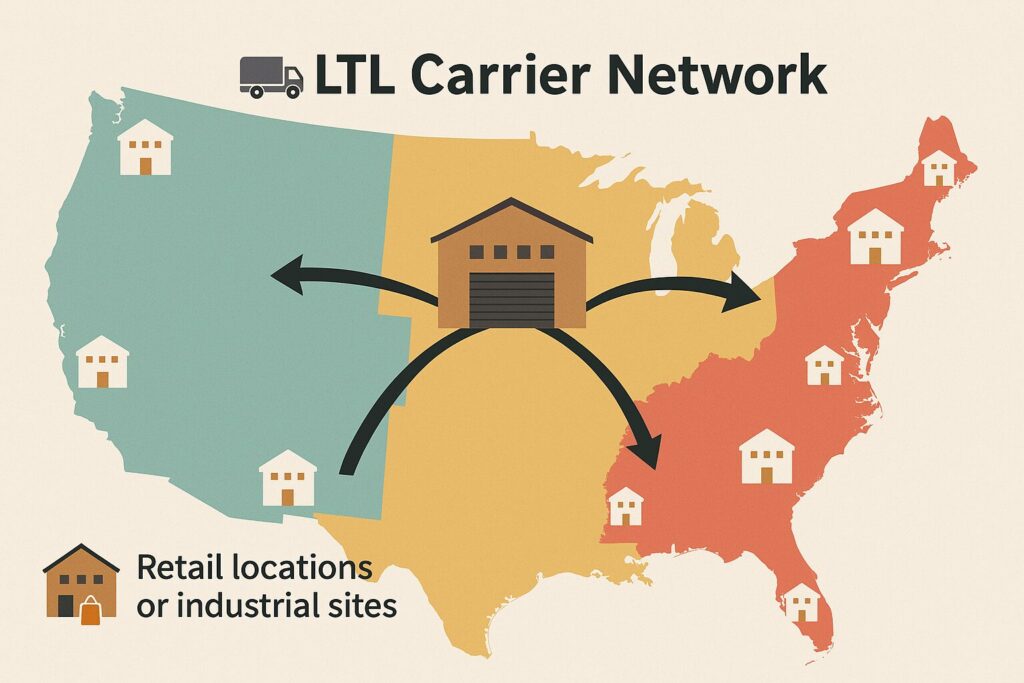

Access to Broader Market Reach

Retailers or manufacturers looking to expand regionally or across the country can tap LTL carriers operating established networks. You gain the ability to ship to multiple geographies without bearing the expense of a dedicated trailer for each region.

When LTL Works Best

Ideal Load Sizes and Transit Priorities

If your pallet count regularly hovers between 1–6 pallets and your total weight remains manageable, LTL is often the best pick. Additionally, if your items aren’t severely time-sensitive, LTL’s typical multi-stop routing may still align with your deadlines. For shipments close to 10 or more pallets, partial truckload solutions or FTL might be more economical or faster.

Matching Commodity Type to Carrier Capabilities

Many LTL providers handle a wide range of commodities, from non-perishable consumer goods to industrial machinery. However, specialized carriers exist for hazmat loads, temperature-controlled freight, or delicate, high-value items. Knowing your product’s specific transport needs ensures you pick carriers experienced in safe, compliant shipping methods.

Key Steps to Prepare for LTL Shipping

Measuring and Weighing Freight Correctly

To secure a precise quote and avoid reweigh fees:

- Weigh your shipment on a calibrated scale, including pallets and packaging.

- Measure dimensions (length, width, height) to evaluate if dimensional or “cube” pricing applies.

- Round up to the nearest inch to avoid accidental misclassification.

Proper Packaging, Labeling, and BOL Details

Robust palletizing is crucial. Use sturdy pallets, shrink-wrap cargo tightly, and add corner protectors if needed. Each parcel or pallet must carry consistent labels—listing origin, destination, and reference numbers. Don’t overlook the Bill of Lading (BOL): a fully completed BOL clarifies who’s paying the freight charges, ensures the correct freight class, and highlights any additional service requests.

Navigating LTL Pricing and Rate Factors

Freight Class, NMFC Codes, and Surcharges

Under the NMFC system, items are assigned a code that dictates their freight class. Fragile or bulky cargo typically commands a higher class (e.g., Class 150 or 200), raising costs, while denser, easily stored freight (e.g., Class 70 or 85) might run cheaper. Also, carriers tack on fuel surcharges that adjust weekly or monthly according to diesel price benchmarks.

How to Compare Carrier Quotes

When requesting quotes, standardize your data—same weight, dimensions, declared value, and extra services—so each carrier or broker provides a comparable rate. Watch out for hidden fees like liftgate usage, limited access, or inside delivery. Request a full breakdown of base rate, fuel surcharge, and potential accessorials to gauge your true shipping expense.

Common LTL Services and Accessorials

Liftgate, Limited Access, and Inside Delivery

Some customers lack a loading dock or forklift, necessitating a liftgate truck to raise or lower pallets. “Limited access” covers schools, military bases, or remote sites that carriers find more challenging to navigate. “Inside delivery” means the driver brings freight beyond the dock or entry door. Each service adds a fee, so pre-communicate special needs to avoid surprise charges.

Handling Hazmat or Temperature-Controlled Freight

While many LTL carriers handle general goods, hazardous materials or refrigerated freight require specialized carriers with proper certifications. They might use reefer trailers for perishable cargo or follow strict hazmat labeling guidelines. These specialized LTL shipments cost more but ensure compliance with safety regulations.

Managing Risks and Insurance

Carrier Liability vs. Additional Coverage

Carrier liability for lost or damaged freight often sits between $0.10–$2.00 per pound, an amount likely insufficient for expensive goods like electronics or specialized parts. If your product’s value surpasses the standard coverage, consider buying supplementary cargo insurance from third-party insurers or your broker to shield against financial losses.

Minimizing Damage or Loss Claims

Preventing damage starts with solid packaging and labeling. Mark shipments as “Fragile” or “Do Not Stack” where relevant. Carriers also see fewer claims if your load is stable and sealed. Checking a potential carrier’s claims ratio or references indicates how often they mishandle freight.

Tracking and Delivery Coordination

Using Carrier Portals or TMS

Carriers typically assign a PRO number to each LTL shipment, which you can track via their website or a Transportation Management System (TMS). Setting up text or email alerts helps you monitor each stop, anticipate arrival times, and quickly rectify any routing errors or delays.

Communicating with Consignees for Seamless Delivery

Ensure your consignee—whether a warehouse, store, or residential address—knows the approximate delivery day/time. If they need an appointment or call-ahead notification, specify this upfront in the BOL. Timely communication prevents carriers from incurring detention charges or second delivery attempts, which could inflate your invoice.

Building Effective Carrier Relationships

Setting Clear Expectations on Service Levels

Whether you ship occasionally or weekly, define:

- Transit Time Goals: The maximum days from pickup to delivery.

- On-Time Delivery Targets: A carrier might commit to 95% or 98% on-time rates.

- Claims Handling: Formalize a procedure for quickly settling damage or loss if it occurs.

Get all terms documented—either in a rate confirmation, email thread, or a short contract for consistent shipments.

Negotiating Rates and Contract Terms

If you ship consistently in certain lanes, carriers might offer discounted contract rates. Clarify the scope (e.g., “at least two pallets each week from Chicago to Houston”) and any conditions for maintaining that rate. Building loyalty fosters better capacity guarantees and responsive customer service, especially in peak seasons or capacity crunches.

Conclusion

LTL freight shipping packs the benefit of pay-per-space efficiency, letting businesses move partial loads swiftly and affordably. However, it also introduces a web of classification rules, surcharges, and multi-stop handling. By grasping core concepts—like freight classes, BOL requirements, and packaging best practices—you can minimize rework, unexpected fees, and damage claims. Meanwhile, forging strong ties to reputable carriers or brokers ensures consistent, reliable deliveries that help you fulfill customer expectations.

Embrace the flexibility of LTL but temper it with diligence: measure your goods thoroughly, specify each service need, communicate effectively, and watch your costs meticulously. Doing so transforms LTL from a logistical wildcard into a stable, integral part of your shipping operations.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.